TECHNOLOGY AND

PERFORMANCE

OFFICINA MECCANICA

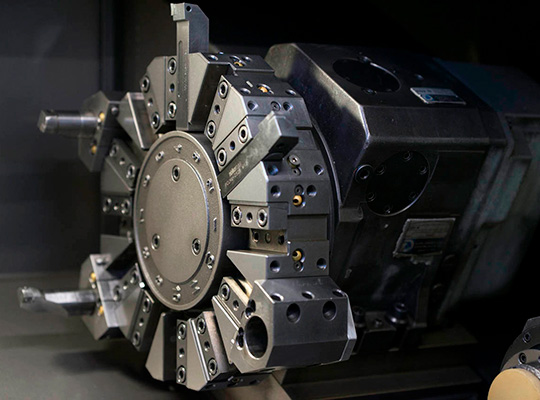

PARCO MACCHINARI

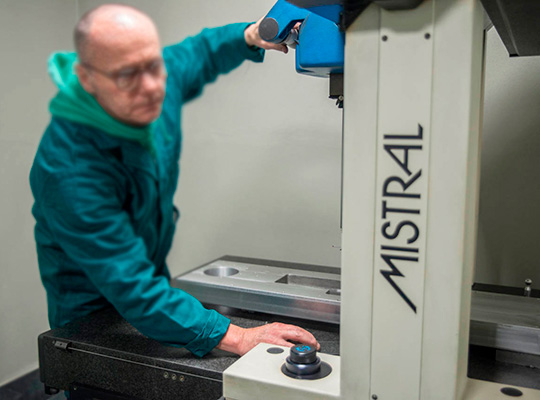

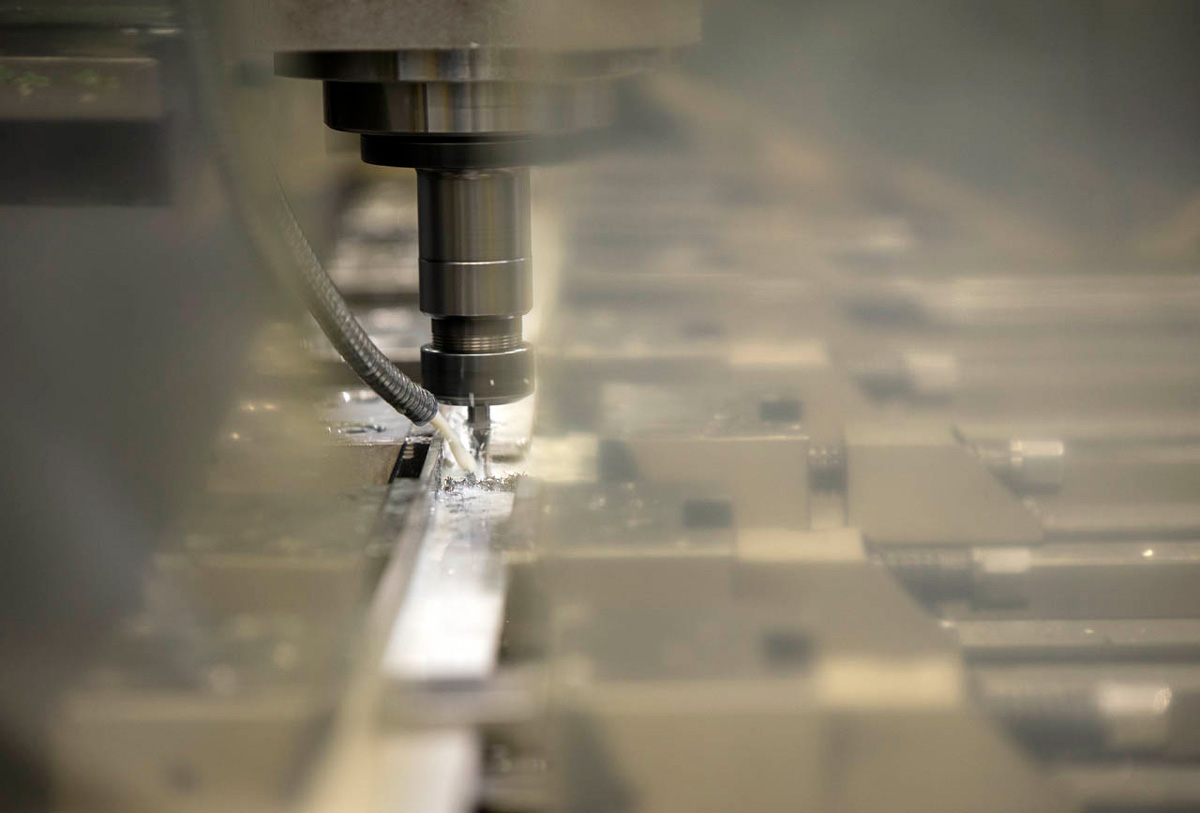

Our equipment includes sophisticated turning machines, milling and boring machines and CNC machines. The process ending with the delivery of products, starts from the purchasing and control of the raw material, goes through the transformation of the drawing by means of CAD/CAM modules and gets to the mechanic processing of single items or big quantities formed by hundreds or thousands of pieces. Our control systems are managed by a CPU having a very low tolerance (+/- 0,05). At the end of the production cycle, the control phase is carried out by means of a dedicated Mitutoyo altimeter with printer and manual measuring machine mod. DEA MISTRALAl DEA MISTRAL 10.07.05, 750x650x450. Our three major areas of specialization are the TURNING, the MILLING and the CNC.

CNC flat, conical, cylindrical, spin-forming, helicoidal and profiling for items made of metal and other materials.

processings by means of CNC milling and boring machines equipped with high-performance CAD/CAM systems.

CNC work units for extremely precise items.

Torneria

Tornio O.M.G. parallelo 260x1500;

Tornio BIGLIA 600/6” mandrino 200x600 CNC completo di unità di governo FANUC OT 8;

Tornio BIGLIA mod.B550 MB diam.200mm CNC, controllo FANUC 18iT;

FRESATURA/ALESATURA/CNC

Fresatrice - Alesatrice BC Technology a banco fisso mod. “F.A.160 CNC” 1600x800x750, controllo HEIDENHAIN 355;

Fresatrice - Alesatrice BC Technology a banco fisso mod. “F.A.160 CNC” 1600x800x750, controllo HEIDENHAIN 355;

Fresatrice - Alesatrice BC Technology a banco fisso mod. “F.A.160 CNC” 1600x800x750, controllo HEIDENHAIN 355;

Fresatrice - Alesatrice FAGIMA a montante mobile orizzontale mod. “MMO 200” 2000x750x100 controllo HEIDENHAIN TNC 360;

Fresatrice - Alesatrice FIL a banco fisso serie “FSG250” 2500x1000x1000, con tavola girevole continua diam. 750mm., controllo numerico continuo HEIDENHAIN TIPO TNC 407;

Fresatrice - Alesatrice FAGIMA a banco mobile mod. “FST400” 4000x2000x1500, controllo numerico continuo HEIDENHAIN TIPO TNC 426 N, versione digitale. Tavola girevole mod. SPARK 10Q mm 1000x1000;

Fresatrice - Alesatrice BC Technology a montante mobile mod. “FMMT600” 6000x1500x1000, controllo numerico HEIDENHAIN TNC640, tavola girevole mod. SPARK 10Q mm 1000x1000.

CENTRI DI LAVORO

Centro di lavoro verticale MICROCUT modello MCV 2416, corse 610x105x510, tavola 760x360, completo di controllo numerico FANUC IMB;

Centro di lavoro verticale 610x410x510 LEADWELL MCV 610 CR, controllo FANUC OM-F completo;

Centro di lavoro verticale 760x510x510 LEADWELL MCV 760 AP con controllo FANUC OM-F, completo di interfacciamento per la gestione del quarto asse continuo;

Centro di lavoro verticale MITSUI SEIKI tipo VS3 AF 760X450X450, completo di controllo numerico FANUC mod. OMC;

Centro di lavoro LEADWELL V30 760x400x510, completo di controllo FANUC 21MB;

Centro di lavoro LEADWELL V50 1270x500x610, completo di controllo FANUC 21MB;

Centro di lavoro verticale di fresatura/foratura CNC DANUSYS 1510S, 1500x1000x1000, controllo HEIDENHAIN iTNC 530;

Centro di lavoro REMACONTROL MOD. LEONARD, COMPLETO DI TAVOLA 5000X820mm, CORSA ASSI Y,Z: 5000X950X1000mm, MAGAZZINO UTENSILI DA 50 POSTI HSK 63, CONVOGLIATORE DI TRUCIOLI, CONTROLLO HEIDENHAIN iTNC 530.

Rettifica

Rettifica tangenziale con piano magnetico 1500x500;

© Copyright 2020 OPAM s.r.l. - All Rights Reserved